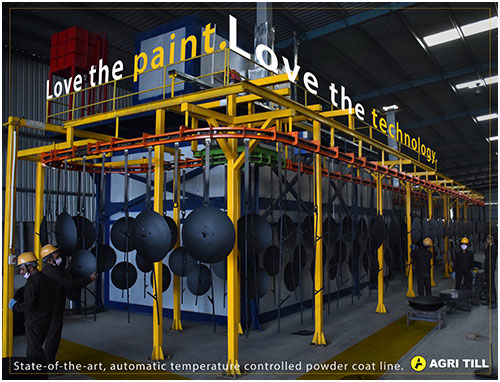

With a manufacturing capacity of a million disc blades, Agri Till utilizes her modern mass-production lines for both boron & high Carbon steel. The steel comes from some of the finest sources in the country that ensure high quality in her blades. One of the first users of Hot Rolled Coil in Boron steel in the country, Agri Till has been at the forefront of product improvement and innovation. At the heart of manufacturing excellence are the heat treatment credentials. Electrical furnaces with temperature controlled zones maintain the right atmosphere for water quenching. This is complemented by state-of-the-art tempering that enhances toughness while maintaining the right hardness. To add colors to the inside-out strong disc blades.

Read More >>Uniform disc blade heating can be quite a challenge. Blades with different diameters and thickness need different heating and soaking cycles. Minor changes in heating condition can vastly affect the hardness and microstructure of the disc blade.

Our state-of-the-art 4 zone electric furnace maintains just the right temperature for each disc blade ensuring conditions for prefect heat treatment.It also eliminates the possibility of disc cracking and disc bending and ensures the blades are ready to be used in any soil condition.

After all, consistency makes all the difference.

The right temperature conditions during quenching restrict the possibility of disc cracking or bending which ensures that the blades can be used in different soil conditions and at high speeds.

After all, consistency makes all the difference.

Efficient, quick and powerful, the high-speed hydraulic press forms the disc blade blanks into the desired profile. Using accurately made dies, the blanks are given consistent concavity and the right shape.

A high-performing coulter and optimal flatness have always gone hand-in-hand. To achieve a high degree of flatness and form varying intricate profiles, our coulter blades are press-quenched. Using precisely made dies and modern control systems, the coulter blade dimensions and tolerances are accurately controlled.

Quenching is a crucial process in determining disc blade hardness and toughness,and it hinges on two key factors: temperature & time. That’s exactly what our modern and accurate fixture quenching system monitors.Equipped with precise temperature sensors, the system is automated to quench the disc blades at a specified temperature range only.

This eliminates the risk of human error, and helps impart uniform and ideal mechanical properties to all our disc blades.